INNOVATION

AUTONOMOUS INFLOW CONTROL DEVICES

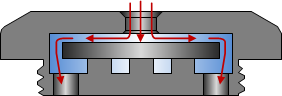

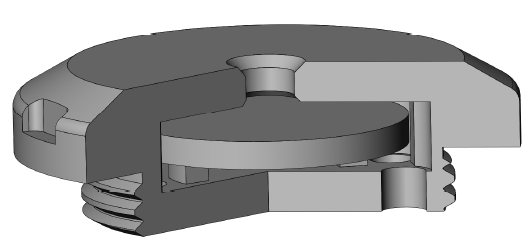

Horizontal wellbores provide access to narrow, oil-bearing formations for maximum contact with pay zones. But when production causes unwanted water and/or gas to migrate to the wellbore, or creates uneven production distribution, operators turn to autonomous inflow control devices (AICDs) to help delay and reduce the flow of unwanted fluids and stimulate balanced production throughout the entire interval. AICDs are inflow control devices that use innovative dynamic fluidic diode technology to distinguish the types of fluids flowing through the device in order to optimize oil production and recovery. They function as passive ICDs during oil production, while restricting the production of water and gas upon breakthrough to minimize water and gas cuts dramatically. AICDs use no moving parts, require no downhole orientation and use the dynamic properties of the fluid to direct flow. All these features enhance long-term functionality and reliability. Fluid Dynamics Technology AICD technology employs a system of flow paths and channels to regulate fluid flow. More specifically, DESHI AICDs incorporate three individual dynamic components—a viscosity selector, a flow switch, and a flow restrictor—all functioning together to allow or restrict flow of fluid without moving parts. The viscosity selector uses a system of flow paths which, based on fluid viscosity, density and velocity, “identifies” the fluid(s) that are flowing through the AICD, and then divides the total flow between two open flow paths. Based on the fluid selector’s output, the flow switch passively directs the majority of the selected fluid down one of the two paths depending on the fluid’s properties. Finally, the flow restrictor restricts the contributing ratio of unwanted fluid (water and/or gas) from entering the wellbore, while providing minimal restriction to the production of the desired fluid.

What Makes an ICD Truly Autonomous? Simply saying an ICD (inflow control device) is autonomous doesn’t mean it’s true. Putting nozzles in series does not make an ICD autonomous; it must do more. To be autonomous, the flow characteristics inside the device must actually change. An autonomous ICD must have a geometry that alters the flow path preferentially restricting the flow of unwanted fluids. An autonomous ICD has the ability to respond to changing well conditions without any action by the operator. When unwanted fluids reach the wellbore, the autonomous ICD changes the way the fluid is moving through the device. This results in increased restriction to flow while other zones producing oil continue production with minimal restriction.